Experience Seamless Operations with a Membrane Switch for Increased Efficiency

Checking Out the Trick Benefits of Membrane Switch Over in Ingenious Layouts

In the world of item layout, the integration of membrane layer switches over deals remarkable benefits, particularly in terms of sturdiness and integrity. These buttons, constructed with layered, adaptable materials, withstand extensive conditions and repeated usage, a vital advantage for tools exposed to extreme settings. Their integral resistance to water, dust, and chemical breach additionally underscores their suitability for numerous commercial applications. This effectiveness, integrated with their visual and useful convenience, positions membrane changes as a compelling choice for developers intending to merge durability with advancement.

Improved Durability and Integrity

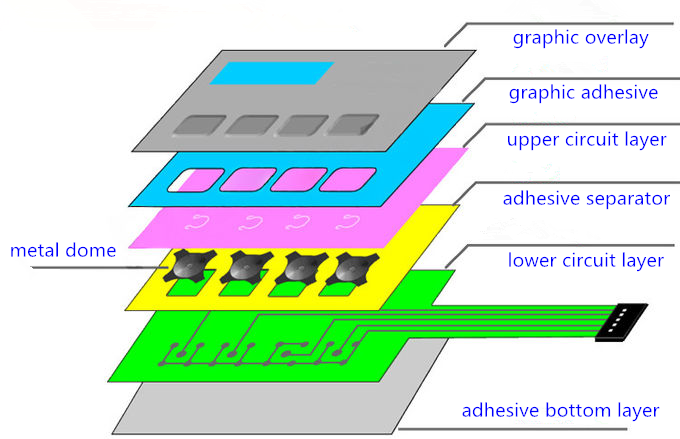

Membrane layer switches are renowned for their enhanced longevity and dependability, associates that originate from their distinct building. These switches are composed of layers including a graphic user interface layer, a conductive ink circuit, and a dielectric layer, all secured versus environmental variables such as dampness and dust. Membrane Switch. This layering not only shields the internal parts yet likewise guarantees that the switch functions under a series of unfavorable problems

Membrane switches also run efficiently in a vast array of temperature levels and are immune to vibrations, making them ideal for use in both commercial and customer applications where dependability is important. Membrane Switch. Their robust building results in fewer failures and maintenance needs

Customization and Aesthetic Versatility

Past their structural benefits, membrane switches deal extensive personalization and aesthetic adaptability to satisfy varied design needs. The visuals overlay, which is the leading layer of a membrane layer button, can be printed with personalized graphics, logo designs, and text, making each application distinct while sticking to brand standards.

Furthermore, the ability to incorporate clear home windows for LEDs or lcds and tactile features such as embossing enriches the individual experience. These alternatives permit the production of a multi-dimensional interface that is not only useful yet also adds to the general product aesthetic appeals. By leveraging these personalization abilities, manufacturers can create distinctive items that stand out in affordable markets.

Cost-Effectiveness and Alleviate of Integration

Additionally, the slim and flexible nature of membrane layer changes allows for uncomplicated integration into numerous applications, from sophisticated medical equipment to customer electronics - Membrane Switch. In addition, membrane switches are suitable with many substrates and adhesives, boosting their flexibility across various sectors.

Final Thought

Finally, membrane layer changes stand out as a robust choice in ingenious designs, supplying improved longevity and reliability critical for withstanding severe conditions. Their ability for customization sustains a wide variety of visual choices, making them versatile for various branding needs. Furthermore, their cost-effectiveness and ease of assimilation promote swift and efficient item advancement, positioning membrane layer switches over as a very helpful Resources option for developers intending to balance capability, design, and marketability in affordable sectors.

In the world of product layout, the assimilation of membrane changes offers notable benefits, specifically in terms of durability and integrity.Beyond their structural benefits, membrane layer changes deal extensive customization and aesthetic versatility to meet diverse layout requirements.While customization boosts visual appeal and functionality, membrane switches additionally provide substantial expense benefits and convenience of integration that profit end-users and suppliers alike. The manufacturing procedure for membrane layer switches over entails fewer products and less labor compared to Learn More conventional mechanical switches, which directly converts into reduced production expenses.In conclusion, membrane layer changes stand out as a durable alternative in cutting-edge layouts, providing improved durability and integrity vital for enduring harsh conditions.